conveyor belt

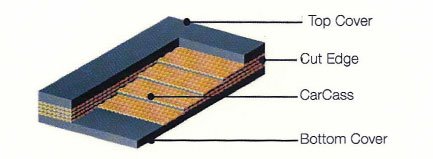

TEXTILE/ FABRICS REINFORCED CONVEYOR BELTS ARE GENERALLY COMPOSED OF THE FOLLOWING COMPONENTS:

Carcass

It provides the tensile strength and body necessary to move the loaded belt. The carcass is made of a numbern of rubberized fabric plies bonded together, such as,cotton-cotton, cotton-nylon, nylon-nylon and polyesternylon fabrics.

It provides the tensile strength and body necessary to move the loaded belt. The carcass is made of a numbern of rubberized fabric plies bonded together, such as,cotton-cotton, cotton-nylon, nylon-nylon and polyesternylon fabrics.

Rubber Cover (Top)

It protects the carcass mainly from impact damage, wear, cut, gauge caused by the material conveyed. It also protects the strength member from effect of oil, heat, flame, chemicals etc as the case may be.

Rubber Cover (Bottom)

It provides good coefficient of friction between the belt and the pulley. Also helps protect the carcass from wear and impact damage from the idlers during carriage of the material and from the material accumulated on the idlers.

RANGE OF NYLON-NYLON POLYSTER- NYLON BELTING

Belt Width : 200 mm to 2400 mm

No. of plies 1 to 7

We have ready stock of Conveyor Belting

1200 mm /1000 mm/900 mm/800 mm/600 mm : 3 & 4 Ply Heavy Duty Belt etc.

Edge : Molded/Protected Edge, Cut Edge

Breaker : Top, Bottom, Floating, Edge

Type of Breaker : Nylon, Polyester

Length :

Standard roll length is 200 meters.

However, tailor -made lengths as per specific requirements can be produced.The restriction on length over and above 200 meters is subject transportable rolldiameter and weight.

Belt Thickness : 3mm to 40 mm

Duty of Belting : Type I, II and III

Cover Grades :

M-24, N-17, M-25, SAR-120, SAR-90, SAR-60, OR, FR, HR/HR- T1 , SHR/HRT-2, HR - T3(180°C), Megaheta (200°C), SSHR (225°C), Hygienic (Food Grade), OR-HR.

Standards Followed :

IS 1891 (Parts I,II,III,IV& V), BS 490, CAN-CSA-M422-M87-C, ISO - 340, ISO 4195(1&11), AS 1332, DIN-22102.